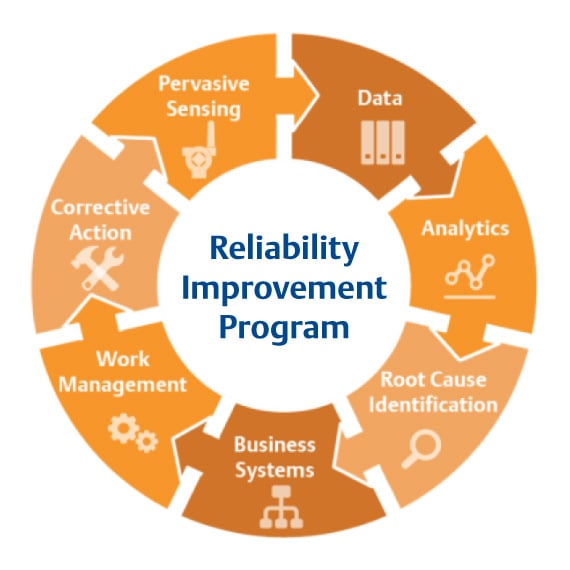

Why Reliability is Critical to Your Organization

Whether you are pursuing asset health improvement for a system, a plant, or an enterprise, the fundamentals are the same. Our experts will help you uncover the obstacles to your success, discover hidden potential within your facility, and develop an implementation plan tailored to your needs. These are the principles of Experitec’s Total Asset Management (TAM), a Predictive Maintenance (PdM) and Reliability Improvement Program.