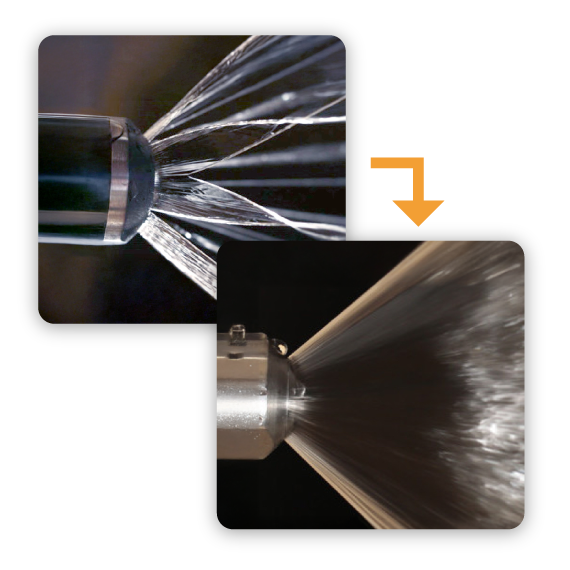

How Long Have You Been Operating

With Severely Damaged Nozzles?

It may be time to consider an ongoing inspection and replacement program for your nozzles, and perhaps a new desuperheater. The steam that you’re producing in your power plant may not be at the required conditions for all applications.